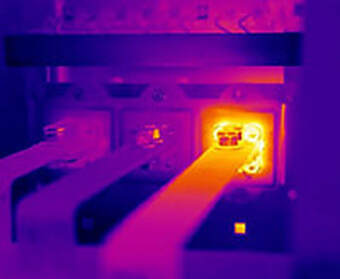

Electrical and Mechanical Thermography

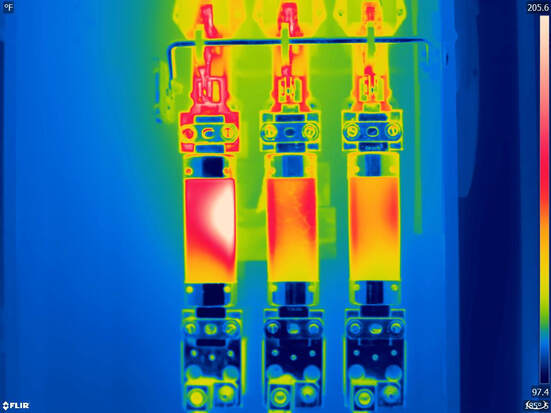

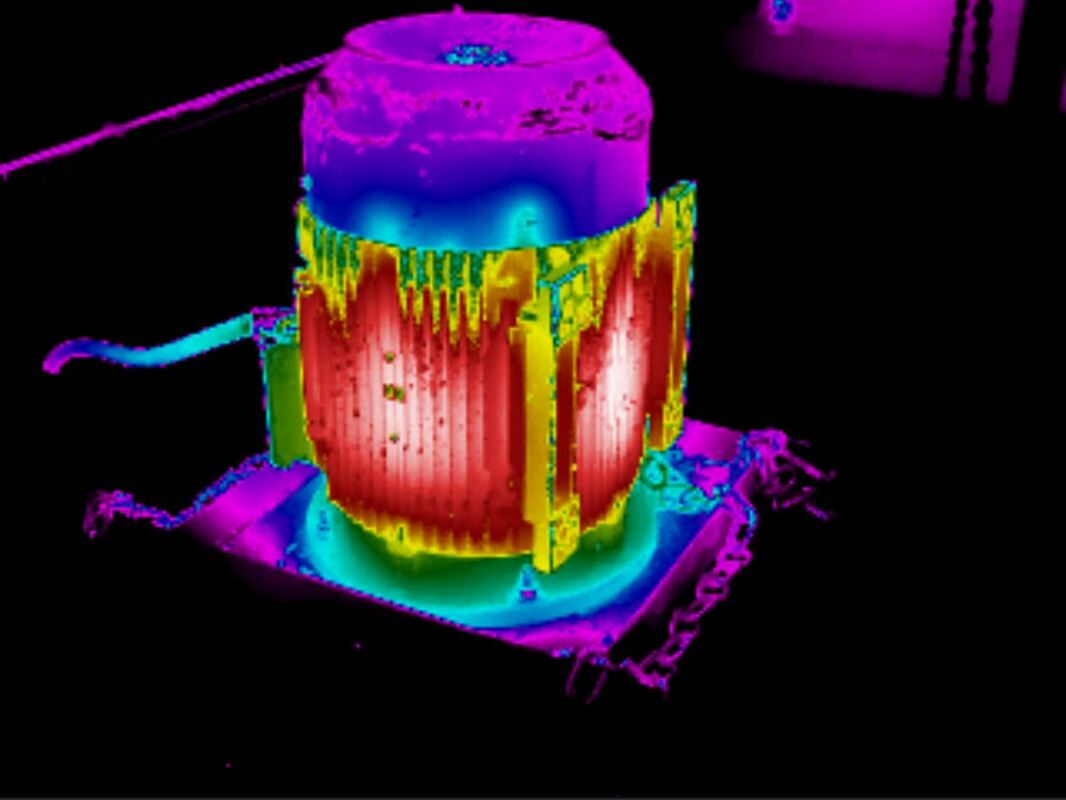

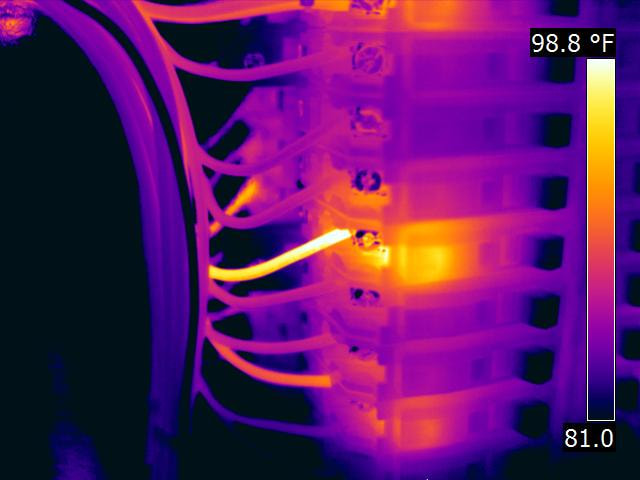

Non-disruptive testing for overloads, loose connections, elevated temperatures, misalignment, and more.

Electrical Thermography is widely used for the inspection of common industrial equipment and components, such as: breaker panels, transformers, bus duct connections, fuses, MCCs, motor starters, distribution belts, bearings, motors, and more.

Thermal Imaging is non-invasive and does not disrupt production. Infrared Thermal Inspections, LLC provides annual Thermography scans, full reports, infrared baselines, diagnostic testing, and travels where you need us, when you need us.

Thermal Imaging is non-invasive and does not disrupt production. Infrared Thermal Inspections, LLC provides annual Thermography scans, full reports, infrared baselines, diagnostic testing, and travels where you need us, when you need us.